KNS 2LGG

This passport applies to the KNS self-regulating heating cable (hereinafter referred to as the cable), which is intended for use in heating systems for pipelines, drainage systems, and the roofs of buildings and structures, including at low temperatures, and in potentially explosive environments.

The cable automatically adjusts its heat output depending on changes in the temperature of the surfaces it is applied to.

The cable can be cut to length based on its technical specifications. The minimum length that can be cut is no less than 0.2 m.

The cable should not be overlapped, nor should its conductors be crossed over or overheated at the splice point.

The same sections of cable can pass through areas with different surface temperatures of the object.

The cable is used for both frost protection systems and heating systems, as well as for heating rooms occupied by people.

Explosion safety is ensured:

- Mechanically stabilized construction.

- External grounding coating that ensures connection to grounding systems for the creation of a reliable grounding circuit.

-

The insulation material exhibits high mechanical resistance, with surface resistance measurements according to item 26.13 of GOST 31610.0 exceeding 10^4 Ohm when at a temperature of 23°C and a relative humidity of 50%±5%.

COMPLIANCE CERTIFICATES

![]() Self-regulating heating cable for single-core installation.

Self-regulating heating cable for single-core installation.

![]() Self-regulating heating cable brands KNS.

Self-regulating heating cable brands KNS.

CONSTRUCTION AND PRINCIPLE OF OPERATION

Construction

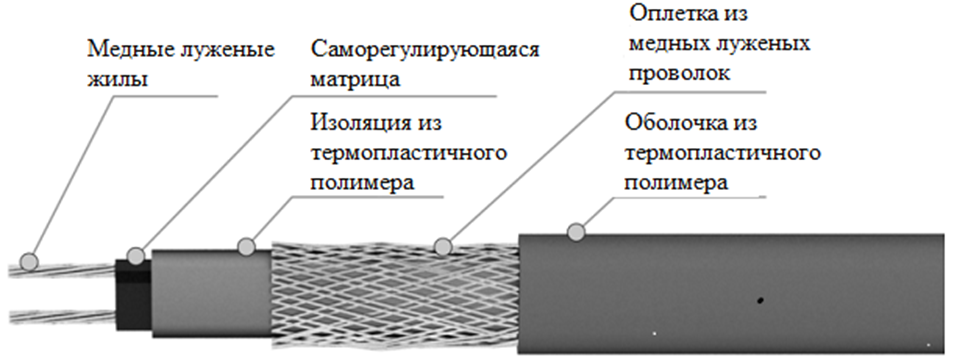

The heating cable consists of the following elements:

- Copper and tinned conductive wires;

- Heat-generating element (polymer self-regulating material with a positive temperature coefficient);

- Insulation;

- Shielding (casing, braid made of tinned copper wire).

- shell;

Principle of Operation

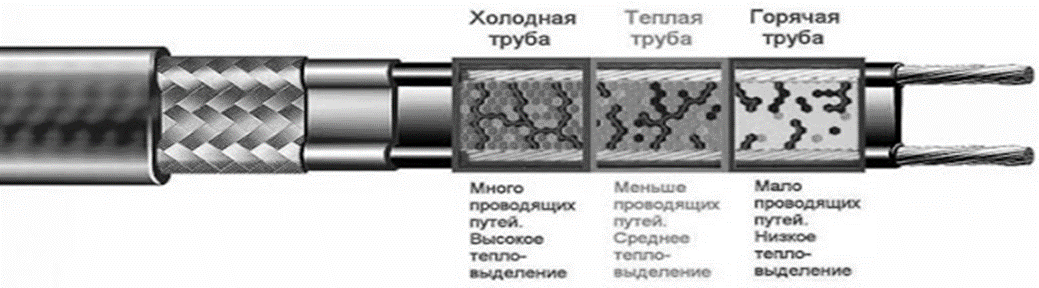

The resistance varies due to the electric current passing through, allowing the self-regulating matrix to draw energy from one conductive wire to another. The self-regulating matrix, combined with the polymer material and shielded wire of the cable, heats the devices. Consequently, the intensity of heat output changes depending on the temperature indicators of the heating surface (as the surface temperature increases, the heat output decreases).

Example of a designation for a self-regulating heating cable of the brand KNS with a nominal output power of 24 W/m, rated for 220V, featuring a conductive core surrounded by a screen made of tinned copper wires, with insulation and sheath made of halogen-free thermoplastic polymer composition, designed for operational and maximum temperatures of 65°C and 85°C for use in domestic and general industrial zones.

24KNS 2LTG-3/1 65/85 UT 27.23.13.136-009-63984293-2021

- The same, with an output power of 30W/m, featuring a conductive core made from nickel-plated copper wire, with insulation and sheath made of polypropylene composition for use in explosion-hazard zones.

30KNS 2NP-3/1 65/85 E1/et 116 tau UT 27.23.13.136-009-63984293-2021

Scheme for forming the conditional designation

CABLE SYMBOL DECODING

|

№ |

PARAMETER |

DESIGNATION |

DECODING |

|

1. |

Cable power |

16,24,30,40 |

Rated power at a temperature of +10°C and a voltage of 220V. |

|

2. |

Cable brand |

KNS |

Electric heating cable, self-regulating |

|

3. |

Supply voltage |

2 |

Voltage range: line 220-240V |

|

4. |

Material of the conductive core |

L |

Tinned copper wires Медная никелированная проволока |

|

5. |

Material of insulation and sheath |

P В ТГ |

hermoplastic polymer composition Поливинилхлоридный пластикат Трудногорючая безгалогенная полимерная композиция |

|

6. |

Electrically conductive sheath |

ZP |

Shielding with tinned copper wires |

|

7. |

Maximum temperature, °C |

65 85 |

Value of allowable temperature Maximum allowable temperature. |

|

8. |

Application zone |

1 |

Used in domestic and general industrial zones |

|

9. |

Special conditions |

Ех |

Special operating conditions |

|

10. |

Presence of connection structure to electrical equipment |

N |

Presence of components for electricity supply |

|

11. |

Voltage of electrical equipment |

V |

Voltage level |

|

12. |

Designation of electrical equipment |

Т6 |

Compliance with modern standards |

|

13. |

Protection of the cable |

E |

Complies with modern standards |

|

14. |

Installation dimensions |

Х |

Compliance with standards |

Purpose and Technical Specifications of the Cable

|

Name |

Cable Brand |

Rated Power at 10 °C, W/m, nominal (220V) |

Max. Operating Temperature °C |

Max. Heating Temperature °C |

|

Heating of pipelines and water supply systems (regular areas) |

16KNS 2LP, 16KNS 2LV, 16KNS 2LGT |

16 |

||

|

24KNS 2LR, 24KNS 2LV, 24KNS 2LPG |

24 |

|||

|

30KNS 2LR, 30KNS 2LV, 30KNS 2LPG |

30 |

65 |

85 |

|

|

40KNS 2LP, 40KNS 2LV, 40KNS 2LPG |

40 |

|||

|

Heating of pipelines and tanks (regular and hazardous areas) |

16KNS 2LP-EL, 16KNS 2LV-EL, 16KNS 2LGT-EL |

16 |

||

|

24KNS 2LP-EL, 24KNS 2LV-EL, 24KNS 2LPG-EL |

24 |

|||

|

30KNS 2LP-EL, 30KNS 2LV-EL, 30KNS 2LPG-EL |

30 |

|||

|

40KNS 2LP, 40KNS 2LV, 40KNS 2LPG |

40 |

|||

|

Floor heating |

40КНС 2ЛП, 40КНС 2ЛВ, 40КНС 2ЛТГ |

40 |

65 |

85 |

|

40KNS 2LP-EL, 40KNS 2LV-EL, 40KNS 2LPG-EL |

||||

|

Protection of drainages and roofs from snow and ice |

30KNS 2LP-EL, 30KNS 2LV-EL, 30KNS 2LPG-EL |

30 |

65 |

85 |

|

40KNS 2LP-EL, 40KNS 2LV-EL, 40KNS 2LPG-EL |

40 |

65 |

85 |

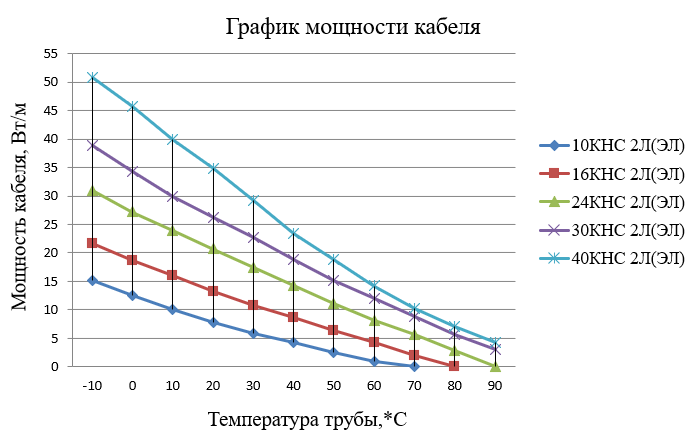

GRAPHS OF CABLE OUTPUT POWER VS. TEMPERATURE

MAXIMUM HEATING CIRCUIT LENGTH

|

Мощность кабеля, Вт/м |

Максимальная длина при использовании автоматического выключателя (ВА) УЗО на 30 мА, м |

Пусковой ток, А/м |

||||

|

Температура включения оС |

Сила тока, А |

|||||

|

10 |

15 |

20 |

30 |

|||

|

16 |

10 |

90 |

135 |

139 |

139 |

0,262 |

|

0 |

71 |

119 |

138 |

138 |

0,285 |

|

|

- 20 |

80 |

105 |

138 |

138 |

0,390 |

|

|

24 |

10 |

64 |

97 |

113 |

113 |

0,483 |

|

0 |

55 |

84 |

111 |

112 |

0,525 |

|

|

- 20 |

44 |

65 |

88 |

111 |

0,601 |

|

|

30 |

10 |

43 |

64 |

87 |

91 |

0,205 |

|

0 |

38 |

58 |

78 |

91 |

0,512 |

|

|

- 20 |

32 |

48 |

64 |

91 |

0,655 |

|

|

40 |

10 |

38 |

57 |

77 |

80 |

0,638 |

|

0 |

35 |

54 |

73 |

80 |

0,740 |

|

|

- 20 |

31 |

47 |

63 |

75 |

0,979 |

|

ПРЕДЕЛЬНЫЕ ОТКЛОНЕНИЯ НОМИНАЛЬНОЙ ВЫХОДНОЙ МОЩНОСТИ КАБЕЛЯ

|

Cable brand |

Мощность, Вт/м |

Температура оС |

||||||||||

|

-10 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

||

|

16КНС 2Л(ЭЛ) |

21,7 |

18,7 |

16 |

13,2 |

10,8 |

8,6 |

6,4 |

4,2 |

2 |

0 |

||

|

24КНС 2Л(ЭЛ) |

30,9 |

27,2 |

24 |

20,7 |

17,4 |

14,3 |

11,1 |

8,2 |

5,6 |

2,9 |

0 |

|

|

30КНС 2Л(ЭЛ) |

38,9 |

34,3 |

30 |

26,2 |

22,7 |

18,8 |

15,2 |

12 |

8,9 |

5,7 |

3,1 |

|

|

40КНС 2Л(ЭЛ) |

50,8 |

45,8 |

40 |

34,8 |

29,2 |

23,5 |

18,8 |

14,2 |

10,3 |

7,1 |

4,3 |

|

CERTIFICATION INFORMATION

1. Certificate of compliance with the requirements of the Technical Regulation of the Customs Union "On the safety of low-voltage equipment" No. EAEU RU C-RU.АЛ36.В.02602/21, issued by JSC "Lider-Compound" by the certification body of the Limited Liability Company "SibPromTest".

2. . Certificate of compliance with the requirements of the Technical Regulation of the Customs Union "On the safety of explosive environments" No. EAEU RU C-RU.АЛ36.В.02270/22, issued by JSC "Lider-Compound" by the certification body of the Limited Liability Company Center "ProdEx".

SAFETY MEASURES

Safety measures for cable installation that are MANDATORY to comply with the warranty conditions:

- Modifications to the cable design are prohibited.

- It is prohibited to apply voltage to the cable while it is still wound on a reel and to preheat the cable on the drum.

- It is prohibited to connect the conductive wires of the cable together to avoid short circuits.

- It is prohibited to operate the cable with parameters that do not match those specified in Table 1 of this passport.

- Welding and work with fire in close proximity to the cable are prohibited to avoid unacceptable external temperature impacts.

- The cable must not be subjected to temperatures above the maximum permissible for its technical specifications according to section 2 of this passport.

- During the installation of the cable line, after completing the installation of the cable ends, it is necessary to check the electrical integrity of the conductors at the joint installation points using a megohmmeter. If the resistance is found to be less than the permissible value during testing, the damaged section of the cable must be removed, and the electrical integrity of the cable conductors must be retested.

TRANSPORTATION, STORAGE, AND DISPOSAL

Transportation and storage of heating cable concerning climatic factors must adhere to the requirements of GOST 15150:

- Heating cables may be transported by all types of covered vehicles. When transporting and handling cargo, the current normative documents must be followed.

- The warranty storage period for the cable is 5 years from the manufacturer.

- The cable should be stored in covered, dry premises with a stacking height of no more than 150 mm.

When storing and transporting the cable, in order to prevent moisture from getting into the conductive sheath and the semiconductive matrix, heat-shrink tubing must be used to ensure airtightness.

The cables are not environmentally hazardous, and there are no specific requirements for their disposal when they are decommissioned, except for the requirements specified in the relevant documentation for nuclear power plants, for example. Burning the cables in household stoves, burners, or bonfires is not permitted.

WARRANTY OBLIGATIONS

The manufacturer guarantees that the cable complies with the technical specifications stated in clause 2 of this Passport.

The warranty period is 5 (five) years from the date of sale of the cable.

The manufacturer's warranty provides for the free replacement of the cable throughout the warranty period, provided that the following conditions are met:

- The cable was used for its intended purpose;

- The installation and operation of the cable were carried out in accordance with the Operating Manual;

- he cable has no mechanical damage that caused malfunctions (including, but not limited to: exposure to liquid, bends, chipping, cracks, and changes in the force applied to connectors and contacts);

- The rules and requirements for the transportation and storage of the cable were followed;

- The Warranty Certificate (Appendix 2 to this Passport) has been completed;

- Information about the cable installation has been entered into Appendix 1 of the Passport.

If, at the time of diagnosis or after it has been conducted, it is found that any of the aforementioned conditions have not been met, the Manufacturer or its representative has the right to refuse warranty repair and/or replacement, issuing a corresponding conclusion.

The warranty is void, and free repair and/or replacement of the product will not be performed in the following cases::

- The warranty period has expired;

- The cable was damaged during transportation after receipt of the product, storage, if the cable was not put into operation, or if the installation and operation rules were violated;

- Damage was caused by natural disasters, fires, and other external factors, climatic and other conditions, or actions by third parties;

- The conditions of the warranty obligations were violated, which is determined in each specific case by the technical specialist of the Manufacturer or its representative;

- The product has already been repaired or has been put into operation after unauthorized repair;

- There were unforeseen natural events, harmful environmental factors, lightning strikes, shocks from falling objects, and other extraordinary circumstances;

- Violations of operational requirements.

-

Corrections have been made in Appendices 1 or 2 to the Passport, without being certified by the seal and signature of authorized representatives of the installation organization and the seller, respectively. In all cases where the cable is not subject to warranty repair, the possibility of paid repair or replacement may be considered at the discretion of the Manufacturer or its representative.

The Manufacturer or its representative is not liable for any losses (including, but not limited to, loss of profits, interruption of business activities, or other financial losses) incurred as a result of improper use or loss of any purchased cable. In any case, the Manufacturer’s liability (or losses) is limited to the cost of the cable provided for replacement, purchased by the customer at the factory, printed circuit boards that connect the cables, or other accessories.

To fulfill the Manufacturer's warranty obligations, please send the following:

- The passport of the cable or its copy with the Quality Control stamp (or another acceptance record);

- The completed Warranty Certificate – Appendix 2;

- The product replacement act including the seller's receipt – Application 2;

- A statement from the purchaser indicating the nature of the malfunction based on the operational conditions, along with the date of sale.