KKNS 2LPP-EL

Designed for heating and maintaining the required temperature in pipes, water systems of buildings and structures, both indoor and outdoor, and for use as part of heating devices for various purposes with a working voltage of up to 240 V AC at a frequency of 50 Hz.

The kit automatically adjusts its heat output depending on changes in the temperature of the surface of the object.

The kit does not emit harmful substances hazardous to humans during operation.

Example of recording the conditional designation of the kit when ordering and in the documentation of another product:

- KKNS kit for use in regular household and industrial areas, with a nominal output of 10 W/m, for use with 220 V voltage, with current-conducting cores of tinned copper wires, with insulation and a sheath made of polyolefin, for a maximum operating temperature under voltage of 65 °C and a maximum exposure temperature of 85°C:

10KKNS 2LP 65/85

- the same, at 16 W for use in regular household and industrial areas, in networks with a grounded conductor, with a nominal output of 10 W/m, shielded with tinned copper wires, with insulation made of food-grade polyolefin, for a maximum temperature under voltage of 65 °C and a maximum exposure temperature of 85°C:

16KKNS 2LPP-EL 65/85

CONSTRUCTION AND PRINCIPLE OF OPERATION

Construction

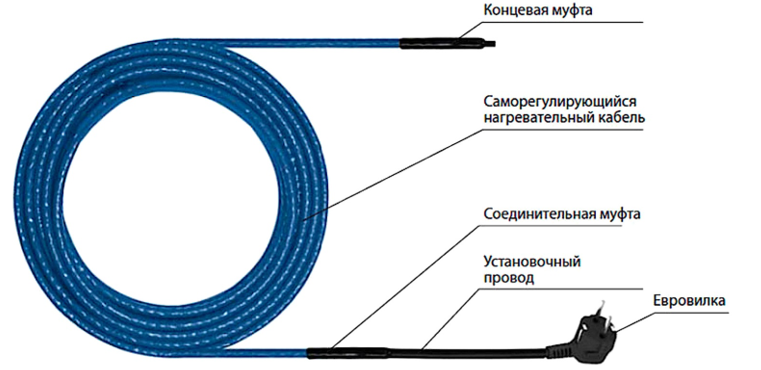

The kit consists of the following elements:

- self-regulating heating cable.

- connecting wire with Europlug (cold lead)

- joint coupling

- end coupling

Operating Principle

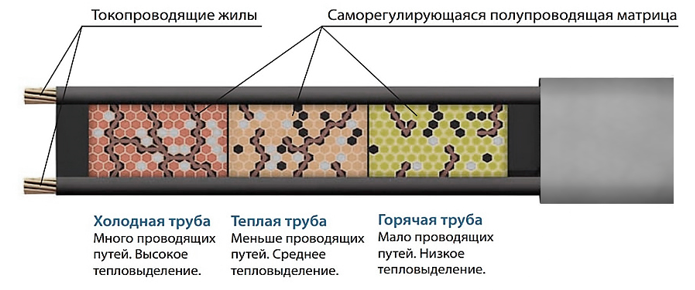

When connected to a power source with the connecting wire (cold lead), electric current passes through the semiconducting self-regulating matrix from one conductive core to another, causing heating due to the electrical resistance of the matrix material. The matrix changes its resistance depending on the temperature of the object where the heating cable is installed. This ensures the self-regulating effect, meaning the linear power of the heating cable changes in response to the change in surface temperature (as the surface temperature increases, the matrix resistance increases, and the power decreases, and vice versa).

CABLE PARAMETERS

|

Operating Voltage |

220 – 240 В |

|

|

Nominal power at +10°C, W/m and voltage 220V |

10 |

16 |

|

Cross-section of conductive core |

0,5 mm2 |

|

|

Diameter of conductive cores |

0,9mm |

|

|

Conductive core material |

Tinned copper wire |

|

|

Semiconducting matrix material |

Polymer composite with positive temperature coefficient (HDPE+CARBON) |

|

|

Insulation material |

Polyolefin |

|

|

Shell conductivity |

Braid of tinned copper wires |

|

|

Electrical resistance of the electrically conductive shell |

Not more than 18.2 Ohm / km |

|

|

Outer insulation material |

Polyolefin |

|

|

Cable outer dimensions (with shield) |

4,7х7,8 (5,26х8,36) |

|

|

Minimum installation temperature 0С |

- 30 |

|

|

Minimum bending radius (with shield), mm |

30(35) |

|

INSTALLATION INSTRUCTIONS FOR THE PIPE KIT

To install the kit in the pipe, you need to separately purchase:

- A pipe tee

Before installing the kit, it is necessary to:

4.1. Turn off the water supply to the pipe (3).

4.2. Install the tee (4) onto the pipe (3).

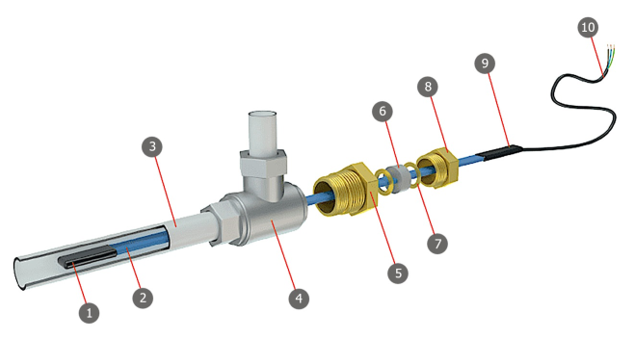

4.3. Carefully inspect the heating cable kit, paying special attention to check for any damage to the end connection (1), the outer sheath of the heating cable (2), the connecting sleeve (9), and the connecting wire (10).

4.4. Disassemble the cable entry into its component parts (5, 6, 7, 8).

4.5. Connect the sealing bushing (5) to the tee. Before connecting, wrap the outer threads of the sealing bushing with sealing tape, thread sealant, or apply sealing paste.

4.6. Screw the sealing bushing into the tee and tighten it using a gas wrench.

4.7. Insert the heating cable (2) into the pipe (3). (The cable entry should occur without significant force. Excessive force when inserting the cable into the pipe may damage the heating cable or its outer sheath.)

4.8. Insert the split sealing (6) into the sealing bushing (5), add the washers (7), and close the bushing with the sealing (8), tightening it with a gas wrench.

4.9. Connect the power cable of the heating kit according to the instructions.

4.10. Turn on the water supply to the pipe and check the connection under working pressure.

4.11. Operate the heating cable kit in accordance with the instructions.

4.12 Inspect the plug of the power cable before connecting.

4.13 Connect the heating cable kit to the power supply network.

NSTRUCTIONS FOR INSTALLING THE KIT ON THE PIPE.

5.1. Prepare the pipeline for installation – clean the pipe surface from dirt and rust.

5.2. Install the self-regulating heating cable on the pipe using one of the methods:

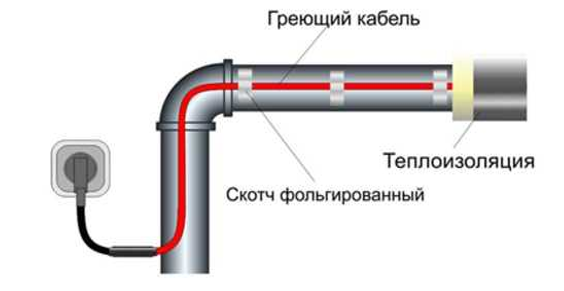

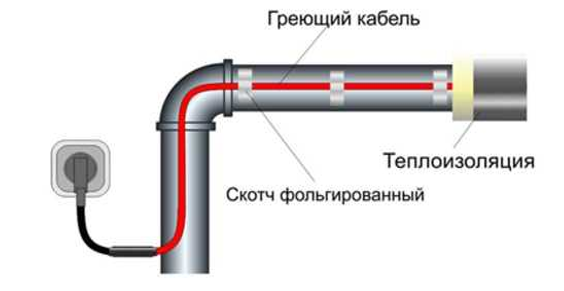

Option 1. Straight installation along the pipe, if necessary, using one or two parallel lines of cable.

Option 2. Helical installation by wrapping with an even pitch, which can be determined according to the data in Table 1 (for metal pipelines) and Table 2 (for plastic pipelines).

5.3. Secure the heating (heating) cable to the lower part of the pipe using fastening tape. Avoid contact with flanged parts and other connections, as this may cause unwanted cable damage. For additional effect, you can pre-wrap the pipe with metal tape for better heat distribution over the pipe surface.

5.4. Install insulation on the pipe, it is recommended to use foil material over the heating cable.

5.5. Connect the heating cable to a power source, connecting the cold end with a high degree of protection, IP54 or higher. If the heating cable is mounted on a pipe located in a remote area from the building, the use of a junction box is recommended.

SAFETY MEASURES

Safety measures for cable installation, which are MANDATORY.

5.1 It is prohibited to install cables at temperatures below 30°C.

5.2 It is prohibited to bend cables during installation with a radius of less than 30mm, and less than 35mm with insulation.

5.3 It is prohibited to connect cables to the electrical network if its parameters do not meet those specified in Table 1 of this instruction.

5.4 The cable should not be exposed to temperatures above the maximum allowable as specified in the technical characteristics according to Table 1 of this instruction.

5.5 The conductive sheath (screen) must be connected to the grounding lead.

5.6 It is prohibited to install in a metal pipe a kit without a conductive sheath (screen).

5.7 For safe operation of the heating cable, it is recommended to use RCDs

devices with a rated current not exceeding 30mA, triggered when the insulation resistance drops below 100m, or power cables.

LIMIT DEVIATIONS OF CABLE NOMINAL OUTPUT POWER

|

Cable brand |

Power, W/m |

Temperature оС |

||||||||||

|

-10 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

|||

|

10KDAC 2(L)P |

15,2 |

12,5 |

10,0 |

7,8 |

5,9 |

4,2 |

2,6 |

1,0 |

0 |

|||

|

16KVDAC 2(L)P |

21,7 |

18,7 |

16 |

13,2 |

10,8 |

8,6 |

6,4 |

4,2 |

2 |

0 |

||

MANUFACTURER'S WARRANTY

7.1 The manufacturer guarantees that the kits meet the requirements of the technical specifications provided that the consumer adheres to the conditions of operation, transportation, storage, and installation established by the technical specifications.

7.2 The warranty period for the kit is 2 (two) years from the date of sale.

7.3 The consumer has the right to request a replacement of the product from the manufacturer during the entire warranty period provided that the following conditions are met:

- compliance with requirements and instructions;

- installation and operation of the cable is carried out in accordance with the installation and operation instructions

- presence of damages that were not caused by the consumer;

- adherence to transportation and storage requirements for the cable