KNS 2LP-EL

This passport applies to self-regulating heating cables KNS (hereinafter referred to as the cable) intended for use in electric heating systems for pipelines, drainage systems, and building and construction roofs for residential and general industrial applications, including in hazardous areas.

The cable automatically adjusts its heat output based on changes in the surface temperature of the object.

The cable can be cut to any length without compromising its technical characteristics. The minimum length of the cable that can be cut should be no less than 0.2 m.

Cables may cross each other without overheating or burning at the intersection.

The same segment of cable can pass through areas with different surface temperatures.

The cable does not emit harmful substances that are dangerous to humans during operation.

Explosion safety is ensured by:

- A stabilized construction

-

The presence of a protective sheath (screen) that allows for connection to grounding systems to create a reliable grounding circuit.

-

The maximum resistance value of the equipotential connection of the sheath, measured in accordance with paragraph 26.13 of GOST 31610.0, should not exceed 10 Ohms at a temperature of (23±2) °C and relative humidity of (50±5)%.

Certificates of Conformity

![]() Self-Regulating Heating Cable for Single Installation

Self-Regulating Heating Cable for Single Installation

![]() Self-Regulating Heating Cable Mark KNS

Self-Regulating Heating Cable Mark KNS

Construction and Principle of Operation

Construction

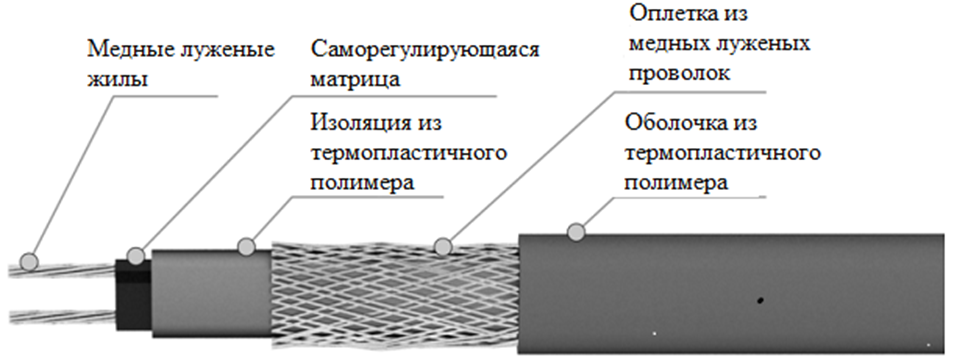

The heating cable consists of the following elements:

- Tinned copper conducting conductors

- Heat-generating element (self-regulating semiconductor matrix) with a positive temperature coefficient

- Insulation

- Conductive sheath (braid made of tinned copper wire)

- Outer sheath

Principle of Operation

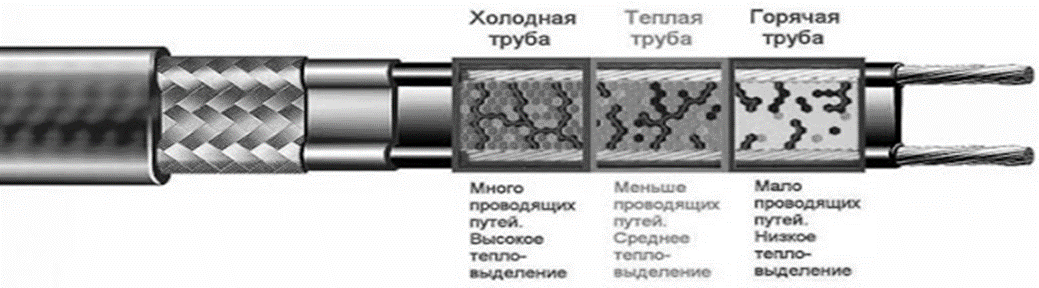

Heating occurs due to the passage of electric current through a self-regulating semiconductor matrix from one conductive conductor to another. The matrix changes its resistance based on the temperature of the surface onto which the heating cable is laid. This provides the self-regulating effect, meaning the linear power of the heating cable changes in response to changes in the surface temperature (as the surface temperature increases, the matrix's resistance increases, and the power decreases, and vice versa).

An example of the designation for a self-regulating heating cable of type KNS with a nominal output power of 24 W/m, operating at a voltage of 220V, with conducting conductor and shield made of tinned copper wires, with insulation and outer sheath made of fire-resistant non-halogen polymer composition, operating and maximum temperatures of 65°C and 85°C for use in residential and general industrial areas:

24КНС 2ЛПГ-ЭЛ 65/85 ТУ 27.32.13.136-009-63982493-2021

- The same, with an output power of 30 W/m, featuring a conducting conductor made of nickel-plated copper wires, with insulation and outer sheath made of polyolefin compositions for use in explosion-proof zones:

30КНС 2НП-ЭЛ 65/85 1Exe IIC T6 Gb X ТУ

Scheme for Forming Conditional Designation

CABLE SYMBOL DECODING

|

№ |

PARAMETER |

DESIGNATION |

EXPLANATION |

|

1. |

Cable Power |

16,24,30,40 |

Nominal power at a temperature of +10 ℃ and a voltage of 220V |

|

2. |

Cable Brand |

KNS |

Electric heating cable, self-regulating |

|

3. |

Supply Voltage |

2 |

AC voltage 220-240 V |

|

4. |

Conductor Material |

L, N |

Tinned copper wire Nickel-plated copper wire |

|

5. |

Insulation and Sheath Material |

P, V, TG |

hermoplastic polymer Polyvinyl chloride plastic Flame-retardant halogen-free polymer composition |

|

6. |

Conductive Shielding |

EL |

Screen made of tinned copper wires |

|

7. |

Maximum Temperature, ℃ |

65 85 |

Maximum operating temperature Maximum allowable temperature |

|

8. |

Explosion Protection Level |

1 |

Explosion protection is ensured both in normal operating modes and in probable failures, depending on operating conditions, except for failures of the means providing explosion protection. |

|

9. |

Special Mark |

Ех |

Indicates compliance of electrical equipment with explosion-proof standards of explosion-proof equipment

|

|

10. |

Type of Explosion Protection Equipment |

е |

Increased type of explosion protection equipment |

|

11. |

Mark of Electrical Equipment Group |

IIC |

Indicates compliance of equipment for use in explosive gas atmospheres |

|

12. |

Temperature Class Mark |

Т6 |

Indicates the maximum temperature at the surface of the shell. |

|

13. |

Explosion Protection Level Mark |

Gb |

High level of explosion protection |

|

14. |

Compliance Mark of Special Conditions |

Х |

Mark indicating adherence to special conditions |

PURPOSE AND TECHNICAL CHARACTERISTICS OF THE CABLE

|

Name |

Марка кабеля |

Rated power at+10 o C, W/m, at 220V |

Макс. рабочая температура нагрева, о С |

Max. operating heating temperature, o C |

|

Pipeline and Water Pipeline Heating (Ordinary Zones) |

16KNS 2LP, 16KNS 2LV, 16KNS 2LGG 16 |

16 |

||

|

24KNS 2LP, 24KNS 2LV, 24KNS 2LGG 24 |

24 |

|||

|

30KNS 2LP, 30KNS 2LV, 30KNS 2LGG 30 |

30 |

65 |

85 |

|

|

40KNS 2LP, 40KNS 2LV, 40KNS 2LGG 40 |

40 |

|||

|

Pipeline and Tank Heating (Ordinary and Explosion Hazard Zones) |

16KNS 2LP-EL, 16KNS 2LV-EL, 16KNS 2LGG-EL 16 |

16 |

||

|

24KNS 2LP-EL, 24KNS 2LV-EL, 24KNS 2LGG-EL 24 65 85 |

24 |

|||

|

30KNS 2LP-EL, 30KNS 2LV-EL, 30KNS 2LGG-EL 30 |

30 |

|||

|

40KNS 2LP-EL, 40KNS 2LV-EL 40 65 85 |

40 |

|||

|

Floor Heating |

40KNS 2LP-EL, 40KNS 2LV-EL 40 65 85 |

40 |

65 |

85 |

|

40KNS 2LGG-EL |

||||

|

Protection of gutters and roofs from snow and ice |

40KNS 2LP-EL, 40KNS 2LV-EL, 40KNS 2LTG-EL |

30 |

65 |

85 |

|

30KNS 2LP-EL, 30KNS 2LV-EL, 30KNS 2LGG-EL 30 |

40 |

65 |

85 |

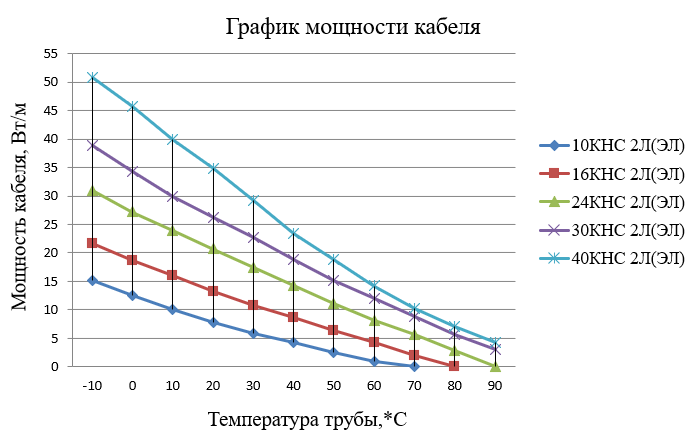

GRAPHS OF THE DEPENDENCE OF CABLE OUTPUT POWER ON TEMPERATURE

MAXIMUM LENGTH OF HEATING CABLE CIRCUIT

|

Cable Power, W/m |

Maximum Length Using Circuit Breaker (A) RCD at 30 mA, m | Starting Current, A/m |

Starting Current, A/m |

||||

|

Switching Temperature оС |

Current, А |

|||||

|

10 |

15 |

20 |

30 |

|||

|

16 |

10 |

90 |

135 |

139 |

139 |

0,262 |

|

0 |

71 |

119 |

138 |

138 |

0,285 |

|

|

- 20 |

80 |

105 |

138 |

138 |

0,390 |

|

|

24 |

10 |

64 |

97 |

113 |

113 |

0,483 |

|

0 |

55 |

84 |

111 |

112 |

0,525 |

|

|

- 20 |

44 |

65 |

88 |

111 |

0,601 |

|

|

30 |

10 |

43 |

64 |

87 |

91 |

0,205 |

|

0 |

38 |

58 |

78 |

91 |

0,512 |

|

|

- 20 |

32 |

48 |

64 |

91 |

0,655 |

|

|

40 |

10 |

38 |

57 |

77 |

80 |

0,638 |

|

0 |

35 |

54 |

73 |

80 |

0,740 |

|

|

- 20 |

31 |

47 |

63 |

75 |

0,979 |

|

IMITING DEVIATIONS OF CABLE NOMINAL OUTPUT POWER

|

Cable Type |

Power, W/m |

Temperature °C |

||||||||||

|

-10 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

||

|

16KNS 2L(EL) |

21,7 |

18,7 |

16 |

13,2 |

10,8 |

8,6 |

6,4 |

4,2 |

2 |

0 |

||

|

24KNS 2L(EL) |

30,9 |

27,2 |

24 |

20,7 |

17,4 |

14,3 |

11,1 |

8,2 |

5,6 |

2,9 |

0 |

|

|

30KNS 2L(EL) |

38,9 |

34,3 |

30 |

26,2 |

22,7 |

18,8 |

15,2 |

12 |

8,9 |

5,7 |

3,1 |

|

|

40KNS 2L(EL) |

50,8 |

45,8 |

40 |

34,8 |

29,2 |

23,5 |

18,8 |

14,2 |

10,3 |

7,1 |

4,3 |

|

PRODUCT CERTIFICATION INFORMATION

1. Certificate of conformity to the requirements of the Technical Regulation of the Customs Union "On the Safety of Low Voltage Equipment" No. EAEU RU C-RU.AБ53.B.02602/21, issued by JSC "Leader - Compound" by the certification body of the limited liability company "SibPromTest".

2. Certificate of conformity to the requirements of the Technical Regulation of the Customs Union "On the Safety of Equipment for Use in Explosive Hazard Areas" No. EAEU RU C-RU.AЖ58.B.02270/22, issued by JSC "Leader - Compound" by the certification body of the limited liability company Center "ProfEx".

SAFETY MEASURES

Safety measures for cable installation, compliance with which is MANDATORY to ensure warranty conditions.

It is prohibited to make independent changes to the design of the cable.

It is prohibited to apply voltage to the heating cable laid in a coil, as well as to carry out heating of the cable on the drum.

It is prohibited to connect the conductive cores of the cable to avoid short circuits.

It is prohibited to connect the cable to an electrical network whose parameters do not match those specified in Table 1 of this Passport.

It is prohibited to carry out welding and fire-related work in close proximity to the cable to avoid unacceptable external temperature impacts.

The cable should not be subjected to temperatures exceeding the maximum allowable values indicated in the technical specifications according to Clause 2 of this Passport.

During installation, it is prohibited to leave the ends of the cable unsealed to prevent moisture from entering the semiconductor matrix of the cable. In the event of accidental damage to the cable, it is forbidden to attempt to repair the damaged section. You must remove the entire damaged section and replace it with a new one using a kit for connecting heating cables. The replacement operations must be carried out immediately after removing the damaged section of the cable to avoid moisture ingress into the cable.

TRANSPORTATION, STORAGE, AND DISPOSAL

The transportation and storage of heating cables, in terms of exposure to climatic factors, must comply with the requirements of OJZ GOST 15150.

Heating cables may be transported by all types of covered vehicles, in accordance with the cargo transportation rules applicable to the respective mode of transport.

The guaranteed storage period for the cable is 5 years in the manufacturer's packaging.

The minimum bending radius of the cable during transportation and storage must not be less than 150 mm.

When storing and transporting the cable, to prevent moisture from entering the electrical insulating sheath and semiconductor matrix, it is necessary to use heat-shrinkable tubing to ensure sealing.

Cables are not considered environmentally hazardous, and there are no special disposal requirements for cables when taken out of service, except for the regulations stipulated in the documentation applicable to nuclear power plants. Burning cables in household stoves, burners, or bonfires is not permitted

WARRANTY OBLIGATIONS

The manufacturer guarantees that the cable complies with the technical specifications indicated in paragraph 2 of this Passport.

The warranty period is 5 (five) years from the date of sale of the cable.

The manufacturer's warranty provides for a free replacement of the cable throughout the warranty period under the following conditions:

- the cable was used for its intended purpose;

- the installation and operation of the cable were carried out in accordance with the Operating Manual;

- the cable has no mechanical damage that caused the malfunction (including, but not limited to: exposure to liquids, bends, chips, cracks in the product, signs of steam exposure, etc.);

- the rules and requirements for the transportation and storage of the cable were followed;

- the Warranty Certificate (Appendix 2 to this Passport) is filled out;

- all installation data for the cable is recorded in Appendix 1 of the Passport.

If, at the time of diagnosis or after it has been conducted, it is determined that any of the listed conditions have not been met, the Manufacturer or its representative has the right to refuse warranty repair and/or replacement, issuing the appropriate conclusion.

The warranty on the cable is voided and free repair and/or replacement of the product is not provided in the following cases:

- The warranty period has expired;

- The cable was damaged during transport after receiving the product, during storage, if the cable was not put into operation, or if the installation and operation rules were violated.

- Damage caused by natural disasters, fire, and other external factors, climatic conditions, or actions of third parties.

- Warranty obligations were violated, as determined by the manufacturer's technical specialist or their representative in each specific case;

- The product shows signs of unauthorized intervention or there was an attempt at unauthorized repair;

- The product has mechanical damage: chips, cracks, dents, tears, scratches, etc., resulting from impacts, falls, or other mechanical influences;

- The requirements of the User Manual for the product were violated;

- Corrections made in Appendices 1 or 2 of the Passport were not certified by the stamp and signature of authorized representatives of the installation organization and the seller, respectively. In all cases where the cable is not subject to warranty repair, the possibility of its paid repair or replacement may be considered at the discretion of the Manufacturer or their representative.

The Manufacturer and their representative bear no responsibility under any circumstances for any damage (including, but not limited to, loss of profits, interruption of business activities, or any other indirect losses) related to the use of the purchased cable. In any case, material compensation, according to the warranty card, can only be provided to the buyer for the cable that caused the losses.

To fulfill the warranty obligations, the Manufacturer or its representative must submit the following documents:

- Product passport with the Quality Control stamp (or a copy certified by the seller's stamp);

- Completed Appendix 1;

- If the product was sold to an individual — completed Appendix 2;

- Customer complaint stating the nature of the defect and operating conditions; a document indicating the date of sale.