KNS 2P

This manual applies to KNS self-regulating heating cables (hereinafter referred to as cables) designed for use in electric heating systems for pipelines, reservoirs, systems and roofs of residential, industrial, and administrative buildings.

The cable automatically adjusts its heat output depending on changes in the surface temperature of the object.

The cable can be cut at any point for the convenience of its installation characteristics. The minimum length of the cut section should be at least 0.2 m.

The same length of cable can pass through areas with different surface temperatures of the object.

Heating sections' ends are covered with a braid for practicality.

Explosion safety is ensured:

- implementation of the stabilization structure

- the presence of an electrically conductive shell (screen) providing connection to deceleration systems to create a reliable deceleration network

- selecting sheath materials with maximum electric resistance on the cable surface, measured according to clause 26.13 GOST 31610.0 not exceeding 10^4 ohm at temperature (23±2) °C and relative humidity (50±5)%

CERTIFICATES OF CONFORMITY

![]() Self-regulating heating cables for single installation

Self-regulating heating cables for single installation

![]() Self-regulating heating cables of the KNS brand

Self-regulating heating cables of the KNS brand

DESIGN AND WORKING PRINCIPLE

Design

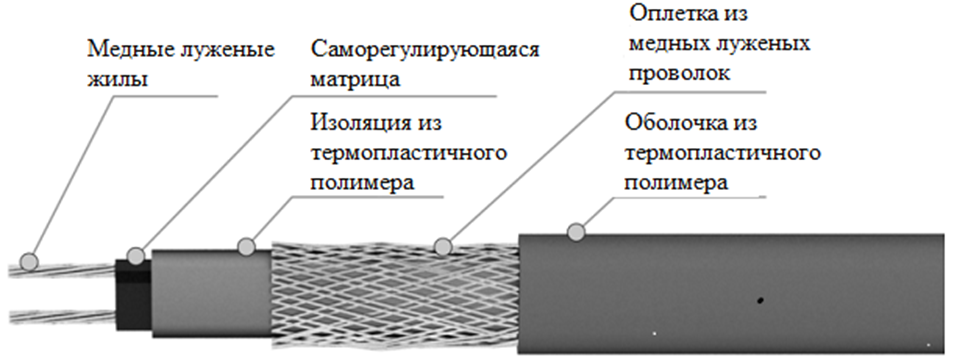

The heating cable consists of the following elements:

- copper stranded conductive wires;

- heat-emitting element (self-regulating semiconductor matrix) with a positive temperature coefficient;

- thermal insulation

- electrical insulation;

- protective sheath (braid made of copper stranded wire).

Working Principle

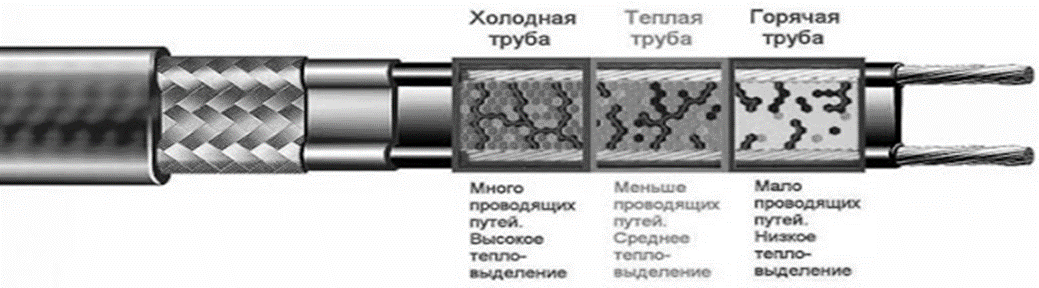

Heating occurs due to the passage of electric current through the self-regulating semiconductor matrix from one conductive wire to another. The matrix has a positive tempera

ture coefficient of resistance, meaning the higher the cable temperature, the less energy is emitted by

Example of the designation for a self-regulating heating cable of type KNS with a nominal output power of 24 W/m, for a voltage of 220E, with a conductive core made of tinned copper wires, with insulation and an outer sheath made of thermoplastic elastomer for operation at temperatures up to 105°C and a maximum temperature of 85°C and 375°C for use in explosive and fire-hazardous areas.

24KNS-2PT-3L/5.5 TU 27.32.13.136-009-63982943-2021

- The same, with an output power of 30 W/m, with a conductive core made of copper, and with insulation and an outer sheath made of composite polyolefins for use in explosive areas.

30КНС-2ПТ-3Л/5.5 IE16 T5 06 K TU 27.32.13.136-009-63982943-2021

Scheme for forming the symbol

DECIPHERING THE CONDITIONAL DESIGNATION OF THE CABLE

|

№ |

PARAMETER |

DESIGNATION |

DECIPHERING |

|

1. |

Cable power |

16,24,30,40 |

Rated power at a temperature of +10°C and a voltage of 220V. |

|

2. |

Cable Brand |

KNS |

Electric heating cable, self-regulating |

|

3. |

Power supply voltage |

2 |

Alternating current voltage of 220-240 V |

|

4. |

Conductive Core Material |

L N |

Copper tinned wire Copper nickel-plated wire. |

|

5. |

Insulation and Sheath Material |

T |

Thermoplastic plastic Polyvinyl chloride plastic Difficult to ignite halogen-free polymer composition. |

|

6. |

Insulation of the outer sheath |

L |

Composite polymers or thermoplastic elastomers |

|

7. |

Maximum temperature, °C |

65 85 |

Maximum allowable temperature Maximum allowable temperature. |

|

8. |

Explosion Protection Level Sign |

1 |

Explosion protection is ensured under both normal operating conditions and in case of potential damage, depending on the operating conditions, except for damage to the means ensuring explosion protection. |

|

9. |

Special Mark for Explosion-Proof Equipment |

Ех |

Indicates compliance of the electrical equipment with standards for explosion-proof equipment. |

|

10. |

Type of Explosion Protection for Equipment |

е |

Increased type of explosion protection for equipment. |

|

11. |

Electrical Equipment Group Mark |

IIC |

Designates a group of electrical equipment intended for use in explosive environments. |

|

12. |

Temperature Class Sign |

Т6 |

Maximum temperature on the surface of the sheath. |

|

13. |

Sign Indicating Compliance with Special Conditions |

XGb |

High level of explosion protection. |

|

14. |

Mark Indicating Compliance with Special Conditions |

Х |

Indicates the necessity for proper connection of the free end of the cable. |

PURPOSE AND TECHNICAL SPECIFICATIONS OF THE CABLE

|

Purpose |

Cable Brand |

Rated Power at +10 °C, W/m, at 220V |

Max. Operating Temperature, °C |

Мax. Heating Temperature, °C |

|

Heating of pipelines and water supply systems (hazardous areas) |

16KNS 2LP, 16KNS 2LV, 16KNS 2LPG |

16 |

||

|

24KNS 2LP, 24KNS 2LV, 24KNS 2LPG |

24 |

|||

|

30KNS 2LP, 30KNS 2LV, 30KNS 2LPG |

30 |

65 |

85 |

|

|

40KNS 2LP, 40KNS 2LV, 40KNS 2LPG |

40 |

|||

|

Heating of pipelines and tanks (flooding and hazardous areas) |

16KNS 2LP-EL, 16KNS 2LV-EL |

16 |

||

|

24KNS 2LP-EL, 24KNS 2LV-EL |

24 |

|||

|

30KNS 2LP-EL, 30KNS 2LV-EL |

30 |

|||

|

40KNS 2LP-EL, 40KNS 2LV-EL |

40 |

|||

|

Floor heating |

16KNS 2LP, 16KNS 2LV, 16KNS 2LPG |

40 |

65 |

85 |

|

40KNS 2LP, 40KNS 2LV, 40KNS 2LPG |

||||

|

Protection of gutters and roofs from snow and ice |

30KNS 2LP, 30KNS 2LV, 30KNS 2LPG |

30 |

65 |

85 |

|

40KNS 2LP, 40KNS 2LV, 40KNS 2LPG |

40 |

65 |

85 |

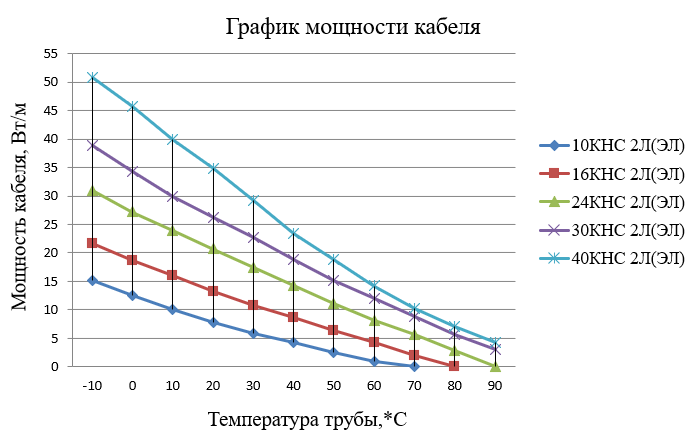

CHARTS OF THE DEPENDENCE OF THE CABLE OUTPUT POWER ON TEMPERATURE

MAXIMUM HEATING CABLE LENGTH

|

Cable power W/m |

Maximum length when using an automatic circuit breaker (RCD) at 30 mA, m |

Inrush current A/m |

||||

|

Switch-on temperature оС |

Current A |

|||||

|

10 |

15 |

20 |

30 |

|||

|

16 |

10 |

90 |

135 |

139 |

139 |

0,262 |

|

0 |

71 |

119 |

138 |

138 |

0,285 |

|

|

- 20 |

80 |

105 |

138 |

138 |

0,390 |

|

|

24 |

10 |

64 |

97 |

113 |

113 |

0,483 |

|

0 |

55 |

84 |

111 |

112 |

0,525 |

|

|

- 20 |

44 |

65 |

88 |

111 |

0,601 |

|

|

30 |

10 |

43 |

64 |

87 |

91 |

0,205 |

|

0 |

38 |

58 |

78 |

91 |

0,512 |

|

|

- 20 |

32 |

48 |

64 |

91 |

0,655 |

|

|

40 |

10 |

38 |

57 |

77 |

80 |

0,638 |

|

0 |

35 |

54 |

73 |

80 |

0,740 |

|

|

- 20 |

31 |

47 |

63 |

75 |

0,979 |

|

ПРЕДЕЛЬНЫЕ ОТКЛОНЕНИЯ НОМИНАЛЬНОЙ ВЫХОДНОЙ МОЩНОСТИ КАБЕЛЯ

|

Марка кабеля |

Мощность, Вт/м |

Температура оС |

||||||||||

|

-10 |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

||

|

16КНС 2Л(ЭЛ) |

21,7 |

18,7 |

16 |

13,2 |

10,8 |

8,6 |

6,4 |

4,2 |

2 |

0 |

||

|

24КНС 2Л(ЭЛ) |

30,9 |

27,2 |

24 |

20,7 |

17,4 |

14,3 |

11,1 |

8,2 |

5,6 |

2,9 |

0 |

|

|

30КНС 2Л(ЭЛ) |

38,9 |

34,3 |

30 |

26,2 |

22,7 |

18,8 |

15,2 |

12 |

8,9 |

5,7 |

3,1 |

|

|

40КНС 2Л(ЭЛ) |

50,8 |

45,8 |

40 |

34,8 |

29,2 |

23,5 |

18,8 |

14,2 |

10,3 |

7,1 |

4,3 |

|

NFORMATION ON PRODUCT CERTIFICATION

1. The certificate of compliance with the requirements of the Technical Regulation of the Customs Union "On the Safety of Low Voltage Equipment" No. EAEU RU C-RU.AБ53.B.02602/21 was issued to JSC "Lider-Compound" by the certification body LLC "SibPromTest."

2. The certificate of compliance with the requirements of the Technical Regulation of the Customs Union "On the Safety of Equipment for Use in Explosive Atmospheres" No. EAEU RU C-RU.AЖ58.B.02270/22 was issued to JSC "Lider-Compound" by the certification body LLC "ProfEx Center.

.

SAFETY MEASURES

Safety measures for cable installation, compliance with which is MANDATORY for warranty conditions.

It is prohibited to make alterations to the structure of the cables independently.

It is prohibited to apply voltage to the heating cable that is coiled, as well as to conduct heating of the cable while it is on the drum.

It is prohibited to connect the conductive conductors of the cable together to avoid short circuits.

It is prohibited to connect the cable to an electrical network whose parameters do not match those specified in Table 2 of this Passport.

When performing welding and work with fire near the cable, measures should be taken to prevent unacceptable external temperature effects.

The cable must not be exposed to temperatures exceeding the maximum allowable values specified in the technical specifications according to Section 2 of this Passport.

During installation, it is prohibited to leave the ends of the cable unsealed to avoid moisture entering the semiconducting matrix of the cable. In the event of accidental damage to the cable and insulation of the conductive conductors, the actions specified in the product manual must be followed. Emergency repairs may involve replacing damaged heating cables. The emergency repair operation may be carried out immediately after removing the damaged section of the cable and providing an adequate reserve.

TRANSPORTATION, STORAGE, AND DISPOSAL

The transportation and storage of the heating cable, considering the impact of climatic factors, must comply with the requirements of OKZ GOST 15150.

The heating cable may be transported by all types of covered vehicles, in accordance with the cargo transportation rules applicable to that type of transport.

The warranty storage period for the cable is 5 years from the manufacturer's packaging date.

The minimum bending radius of the cable during transportation and storage must not be less than 150 mm.

To maintain the cable in proper condition and avoid moisture exposure to its semiconducting matrix, protective packaging or other effective measures should be utilized.

The cable does not release hazardous substances into the ecological system and can be disposed of as household waste when no longer in use, in accordance with the operational regulations applicable to this field. It is prohibited to glue cables while in coils, on drums, or in packaging.

WARRANTY OBLIGATIONS

The manufacturer guarantees that the cable complies with the technical specifications stated in clause 2 of this Passport.

The warranty period is 5 (five) years from the date of sale of the cable.

The manufacturer's warranty provides for the free replacement of the cable throughout the warranty period, provided that the following conditions are met:

- The cable was used for its intended purpose;

- The installation and operation of the cable were carried out in accordance with the Operating Manual;

- The cable has no mechanical damage that caused malfunctions (including, but not limited to: exposure to liquid, bends, chipping, cracks, and changes in the force applied to connectors and contacts);

- The rules and requirements for the transportation and storage of the cable were followed;

- The Warranty Certificate (Appendix 2 to this Passport) has been completed;

- Information about the cable installation has been entered into Appendix 1 of the Passport.

If, at the time of diagnosis or after it has been conducted, it is found that any of the aforementioned conditions have not been met, the Manufacturer or its representative has the right to refuse warranty repair and/or replacement, issuing a corresponding conclusion.

The warranty is void, and free repair and/or replacement of the product will not be performed in the following cases:

- The warranty period has expired;

- The cable was damaged during transportation after receipt of the product, storage, if the cable was not put into operation, or if the installation and operation rules were violated;

- Damage was caused by natural disasters, fires, and other external factors, climatic and other conditions, or actions by third parties;

- The conditions of the warranty obligations were violated, which is determined in each specific case by the technical specialist of the Manufacturer or its representative;

- The product has already been repaired or has been put into operation after unauthorized repair;

- There were unforeseen natural events, harmful environmental factors, lightning strikes, shocks from falling objects, and other extraordinary circumstances;

-

Violations of operational requirements.

-

Corrections have been made in Appendices 1 or 2 to the Passport, which have not been certified by the seal and signature of authorized representatives of the installation organization and the seller, respectively. In all cases where the cable is not subject to warranty repair, the possibility of paid repair or replacement may be considered at the discretion of the Manufacturer or its representative.

The Manufacturer or its representative is not liable for any losses (including, but not limited to, loss of profits, interruption of business activities, or other financial losses) incurred as a result of improper use or loss of any purchased cable. In any case, the Manufacturer’s liability (or losses) is limited to the cost of the cable provided for replacement, purchased by the customer at the factory, printed circuit boards that connect the cables, or other accessories.

To fulfill the Manufacturer's warranty obligations, please send the following:

- The passport of the cable or its copy with the Quality Control stamp (or another acceptance record);

- The completed Warranty Certificate – Appendix 2;

- The product replacement act including the seller's receipt – Application 2;

- A statement from the purchaser indicating the nature of the malfunction based on the operational conditions, along with the date of sale.